Argon is used as a protective atmosphere for a large number of industrial processes, including steel manufacturing, welding and metal fabrication, electronics, food preservation and winemaking.

The Role of Industrial Argon in Various Industries

Argon plays a significant role in many industries. As an inert, colorless, and odorless gas, it is non-reactive, making it ideal for applications that require a stable environment. In this article, we will explore how industrial argon is used across various sectors and why it’s essential for many applications.

What is Industrial Argon?

Industrial argon is a highly purified form of argon gas, which is used in a wide range of industries. Its chemical stability makes it the go-to gas for processes where other substances must be shielded from reactions. Because of these characteristics, it’s a critical component in ensuring the success of various industrial applications.

Common Uses of Argon

- Welding and Metal Fabrication

Argon is essential in welding, as it acts as a shielding agent to protect the weld area from oxidation and contamination. Additionally, it helps ensure smooth, high-quality results, particularly in processes like TIG welding. By maintaining an inert atmosphere, argon plays a pivotal role in achieving precise welds.

- Electronics and Semiconductor Manufacturing

In the electronics industry, argon is used during semiconductor manufacturing. It helps maintain an oxygen-free environment, preventing oxidation during sensitive processes. Without argon, it would be nearly impossible to achieve the high-quality results required for electronic components.

- Food and Beverage Industry

Interestingly, argon also has applications in the food industry. It is used in packaging to replace oxygen, thus slowing down the oxidation process. As a result, food stays fresh for longer, which is particularly beneficial for preserving the quality of perishable items.

- Lighting Industry

Argon is used in the production of incandescent light bulbs. By filling the bulb with argon gas, manufacturers can prevent the filament from burning too quickly, ultimately increasing the lifespan of the bulb. Without argon, light bulbs would burn out much sooner.

- Medical Applications

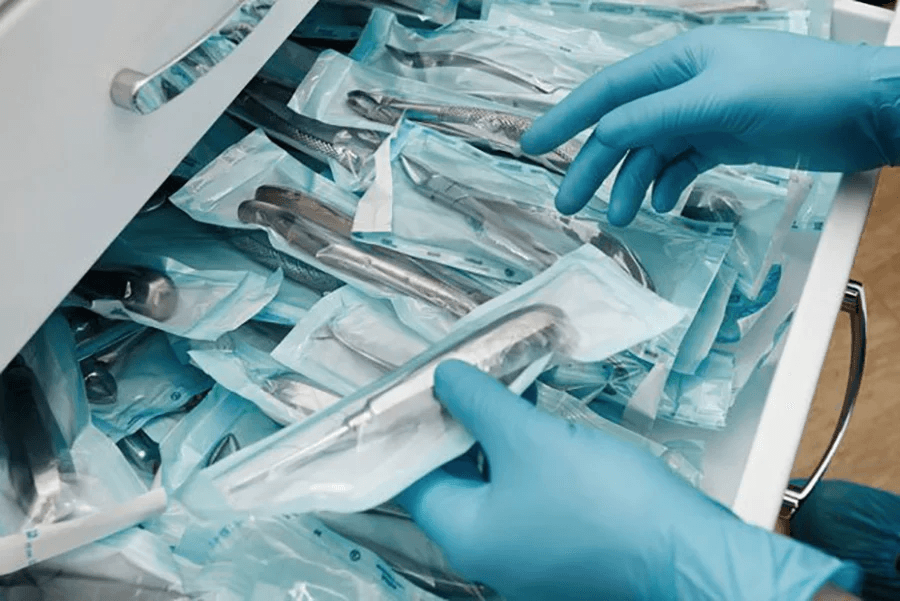

In medicine, argon is used in cryotherapy and other medical procedures. It helps cool instruments during surgery and plays a vital role in certain medical imaging equipment. Its non-reactive properties make it safe for use in medical environments.

Benefits of Using Argon

- Non-reactive Properties: Argon’s stable nature ensures that it doesn’t react with other substances, making it safe for high-precision applications.

- Control and Precision: The gas creates a controlled environment, which allows industries to achieve accurate, high-quality results.

- Cost-Effectiveness: Despite its higher price compared to other gases, argon’s benefits—such as improving product quality and reducing defects—make it a worthwhile investment.

Conclusion

In conclusion, industrial argon is a vital gas used in multiple sectors, ranging from manufacturing to food preservation and medical uses. Its unique properties, such as being non-reactive and offering control during sensitive processes, ensure that it remains indispensable in industries that require precision and reliability. As demand for high-quality products increases, argon will continue to be a key resource for various applications.