Acetylene and ethylene are two vital hydrocarbons with widespread applications across various industries. Both gases play significant roles in chemical synthesis, welding, and other industrial processes. This article explores their key differences, applications, and the critical role they play in modern manufacturing.

What are Acetylene and Ethylene?

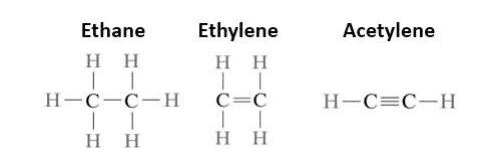

Acetylene (C2H2) and ethylene (C2H4) are simple hydrocarbons belonging to the alkynes and alkenes groups, respectively. While both share similar elemental compositions, their molecular structures, properties, and industrial uses vary significantly.

Acetylene: The Triple-Bonded Alkyne

- Chemical Formula: C2H2

- Structure: Linear molecule with a triple bond between carbon atoms

- Key Properties: Highly reactive, flammable, and produces intense heat during combustion

Ethylene: The Double-Bonded Alkene

- Chemical Formula: C2H4

- Structure: Planar molecule with a double bond between carbon atoms

- Key Properties: Versatile, mildly reactive, and widely used as a precursor in chemical synthesis

Key Differences Between Acetylene and Ethylene

Understanding the differences between acetylene and ethylene is crucial for choosing the right gas for specific applications.

| Aspect | Acetylene (C2H2) | Ethylene (C2H4) |

|---|---|---|

| Bond Type | Triple bond (alkyne) | Double bond (alkene) |

| Stability | Less stable; highly reactive | More stable; moderately reactive |

| Applications | Welding, cutting, synthesis of PVC | Polymer production, agriculture |

| Flammability | Extremely flammable | Highly flammable |

| Energy Output | Produces high heat during combustion | Lower heat output |

Applications of Acetylene

1. Welding and Cutting

Acetylene is widely used in oxy-acetylene welding and cutting. Its ability to produce high-temperature flames makes it ideal for joining and cutting metals.

2. Chemical Synthesis

Industries use acetylene as a raw material in synthesizing chemicals such as vinyl chloride (used in PVC production) and acetaldehyde.

3. Lighting

Although less common today, acetylene was historically used in carbide lamps for lighting before the advent of electric lights.

Applications of Ethylene

1. Polymer Production

Ethylene is a cornerstone for producing polyethylene, one of the most widely used plastics globally. It also plays a role in manufacturing other polymers like PVC and polystyrene.

2. Agriculture

Ethylene acts as a plant hormone, regulating fruit ripening. Farmers and food industries use ethylene to accelerate ripening during transportation.

3. Chemical Synthesis

Ethylene serves as a precursor in producing ethylene oxide, ethylene glycol, and other essential industrial chemicals.

Why Acetylene and Ethylene are Vital for Industry

Both acetylene and ethylene are indispensable due to their unique properties and applications.

- Acetylene is essential for processes requiring intense heat, such as welding and cutting.

- Ethylene is the backbone of modern polymer production, supporting the global demand for plastics and chemicals.

By understanding their distinct roles, industries can maximize efficiency and output in their operations.

Safety Considerations for Acetylene and Ethylene

Given their flammability, both gases require careful handling to prevent accidents:

Storage Guidelines:

- Acetylene: Must be stored in specially designed cylinders with porous materials to prevent explosive decomposition.

- Ethylene: Stored under pressure in gas cylinders or as a cryogenic liquid.

Handling Tips:

- Ensure proper ventilation in storage and work areas.

- Use flame arrestors and pressure regulators to control gas flow.

- Train personnel on the properties and risks associated with these gases.

Partner with Trusted Suppliers for Acetylene and Ethylene

Choosing a reliable supplier is crucial for ensuring the quality and safety of acetylene and ethylene. Jinhong Gas, a leading gas manufacturer, provides high-purity acetylene and ethylene tailored to industrial needs.

Why Choose Jinhong Gas?

- High-Quality Products: Each batch meets rigorous quality standards.

- Customized Solutions: Flexible supply options for diverse industries.

- Technical Support: Expert guidance on safe handling and efficient usage.

- Global Network: Reliable delivery services to customers worldwide.

Frequently Asked Questions

1. How do acetylene and ethylene differ in terms of stability?

Acetylene is less stable due to its triple bond, while ethylene’s double bond makes it more stable and versatile.

2. Can acetylene be used for polymer production?

No, acetylene is not typically used for polymer production. Ethylene is the preferred choice for creating plastics and other polymers.

3. How does Jinhong Gas ensure the safe supply of acetylene and ethylene?

Jinhong Gas adheres to strict safety and quality protocols, ensuring safe storage, transportation, and delivery of these gases.

Conclusion

Understanding the properties and applications of acetylene and ethylene enables industries to leverage their strengths effectively. Whether for welding, chemical synthesis, or polymer production, these gases remain vital to modern manufacturing.

Contact Jinhong Gas today for premium acetylene and ethylene supplies tailored to your business needs.