Shielding Gas Argon: Why It’s Essential for Welding

Argon, a colorless, odorless, and inert gas, is widely used in welding as a shielding gas. By providing a protective barrier, it prevents contamination from atmospheric gases like oxygen and nitrogen, ensuring high-quality welds. This article highlights the importance of shielding gas argon, its role in welding, and its benefits across multiple industries.

What Is Shielding Gas Argon?

Shielding gas argon is used to create an inert atmosphere around the weld, protecting it from harmful contaminants. Its inert properties make it ideal for welding processes such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. Argon’s ability to prevent oxidation and contamination ensures that the welds remain strong and clean, with minimal defects.

Why Argon is Vital for High-Quality Welds

- Prevents Oxidation and Contamination

Argon is effective in shielding the molten metal from reactive gases. This ensures the weld pool remains free from contamination, especially when welding metals like stainless steel and aluminum. By preventing oxidation, argon ensures that the final weld is durable and of high quality.

- Stable Arc Production

Another key benefit of shielding gas argon is its ability to create a stable arc. A stable arc is crucial for precise welding, especially on delicate or complex projects. This stability also reduces spatter, resulting in cleaner and smoother welds.

- Versatility Across Various Materials

Argon is compatible with many metals, including aluminum, stainless steel, and titanium. Its versatility makes it an essential gas for various welding applications, whether you’re working with lightweight materials or more durable metals.

Applications of Shielding Gas Argon in Welding

Argon is widely used in industries that require precise and high-quality welding. Below are some examples:

- Aerospace Industry

The aerospace industry requires flawless welds for aircraft and spacecraft components. Argon’s shielding capabilities ensure that welds are strong and free from defects, which is vital for safety and performance.

- Automotive Manufacturing

Argon is used to weld parts of cars, such as exhaust systems and body panels. Its stable arc and shielding properties ensure clean and durable welds, which are essential for automotive safety.

- Steel Manufacturing

In steel production, argon helps produce high-quality welds for components like pipelines and structural frames. The stable environment created by argon ensures the integrity and strength of the welds.

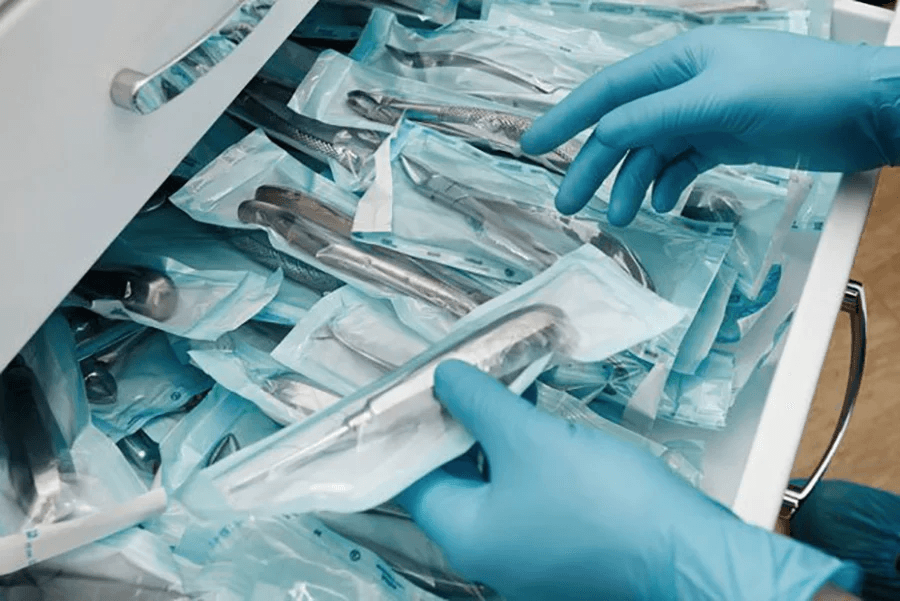

- Medical Device Production

The medical device industry relies on argon to create precise, contamination-free welds. Whether it’s for surgical instruments or implants, argon ensures that the welding process is both clean and reliable.

Benefits of Using Shielding Gas Argon in Welding

- Improved Weld Quality: Argon ensures that the weld is free from oxidation and contamination, resulting in a cleaner and more durable weld.

- Reduced Spatter: The stable arc created by argon helps minimize spatter, reducing the need for post-weld cleanup.

- Enhanced Control: Argon allows for better control over the welding process, especially when working with intricate designs or thin materials.

Tips for Using Argon Effectively in Welding

- Choose the Right Purity: For optimal results, use high-purity argon (99.9% or higher) to ensure the best possible welds.

- Maintain Proper Gas Flow: Make sure to adjust the gas flow rate according to the welding requirements. Too much or too little gas can affect the quality of the weld.

- Use the Right Equipment: Ensure that your welding machine is compatible with argon to get the most out of the shielding gas.

Why Shielding Gas Argon Is a Smart Investment

Investing in shielding gas argon offers several advantages, including enhanced weld quality, increased efficiency, and environmental benefits. Argon is a naturally occurring, non-toxic gas, making it an eco-friendly choice for industries seeking sustainable practices.

Conclusion

In conclusion, shielding gas argon is an essential component for high-quality welding. Its ability to create stable arcs, prevent oxidation, and produce clean, strong welds makes it the gas of choice for industries like aerospace, automotive, and medical device manufacturing. Whether you’re working on a large-scale project or a precision task, argon ensures that your welding process is efficient and effective.

By selecting the right purity and equipment, you can achieve superior welds with shielding gas argon every time. If you’re unsure about which shielding gas to use, argon is always a safe and reliable choice for achieving professional-quality results.