PSA nitrogen generator is a nitrogen generation device based on Pressure Swing Adsorption (PSA) technology. It is primarily used to separate high-purity nitrogen from air and finds widespread applications in industries, laboratories, and medical fields. PSA Nitrogen Machine Technology is a very mature technology and has been around since the 1970’s. In fact, thousands of PSA plants are serving customers worldwide.

| N2 Output | Purity | Pressure | Temperature |

| 50-500Nm3/h | 99%-99.99% | 0-0.8MPa | Room Temp. |

| 50Nm3/h | 100Nm3/h | 150Nm3/h | ≥200Nm3/h |

| 4300*2300*2800 | 4900*2500*3100 | 8400*2100*3500 | Designed Accordingly |

PSA nitrogen generator is a nitrogen generation device based on Pressure Swing Adsorption (PSA) technology. It is primarily used to separate high-purity nitrogen from air and finds widespread applications in industries, laboratories, and medical fields.

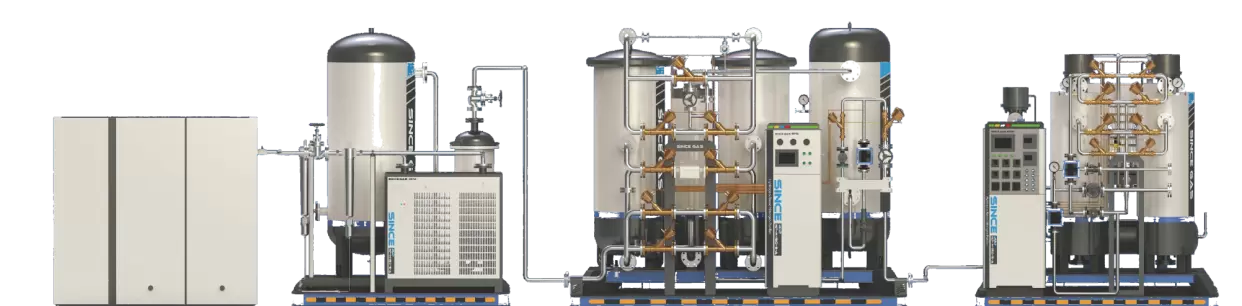

We divide the nitrogen produced by the nitrogen generator into normal nitrogen (purity 95%-99.99%) and high purity nitrogen (purity 99.995%-99.9997%). Normal nitrogen is produced as shown in the above diagram and is divided into three main components: air compressor, air purification system and nitrogen production system. The air purification system can be equipped with a cold dryer, an adsorption dryer or a combination dryer as required, and the nitrogen n2 generator can be equipped with the corresponding storage tank as required. These three components will be briefly introduced below.

The compressed air system consists of a compressor and an air buffer tank (to provide the compressed air required for the VPS nitrogen/oxygen plant). The process requires the system to provide a stable output pressure and sufficient air volume. The air compressor is an oil-injected screw compressor with reliable operation, simple maintenance, low noise and no base operation.

The compressed air from the buffer tank first enters the 9-stage filter and then enters the refrigerated dryer. The compressed air is allowed to cool down forcibly so that the water vapour in the air condenses and condenses into liquid water entrained with dust and oil and is discharged from the machine.

The latter stage of the cold dryer is the precision filter group, which consists of two stages of filters. These are the 7-stage main line filter and the 3-stage high efficiency oil mist removal filter.

The 7-stage air supply line filter has an accuracy of 1um, which filters out 1um and larger solid and liquid particles, with a residual oil content of 1ppm w/w.

The 3-stage high efficiency oil mist filter with 0.01um filtration accuracy, filtering out 0.01um and larger solid and liquid particles, residual oil content 0.001ppm w/w.

The n2 generator is based on clean compressed air as raw material and carbon molecular sieve as adsorbent, using the principle of variable pressure adsorption to obtain nitrogen at room temperature. According to the difference of oxygen and nitrogen adsorption on the surface of the carbon molecular sieve and the different diffusion rate of oxygen and nitrogen in the carbon molecular sieve, the programmable controller controls the opening and closing of the programmed broad, to realize the process of pressurization adsorption and decompression desorption, to complete the separation of oxygen and nitrogen and get the nitrogen of the required purity.

Flow rate: 3~5500Nm³/h

Dew point: ≤-73℃

Purity: 95%~99.9995%.

Fast start-up, with qualified nitrogen available in 15 to 30 minutes;

Fully automatic operation of the equipment, the whole process can be unattended;

Efficient loading of molecular sieves for tighter, more solid and longer service life;

Stable and adjustable pressure, purity and flow rate to meet the different needs of customers;

Reasonable structure, advanced processes, safety and stability, low energy consumption;

The nitrogen purification plant designed by our company is a traditional hydrogenation and deoxygenation type nitrogen purification process. The principle is to use a special 506HT palladium catalyst to remove impurities of oxygen, water vapour and dust from the nitrogen by means of catalysis, adsorption and filtration to obtain high purity nitrogen with 99 % purity nitrogen from the nitrogen generator as raw material. And the specially formulated palladium catalyst type 506HT allows the oxygen in the nitrogen to react chemically with hydrogen under the action of catalysis as follows:

2H2+O2 == 2H2O

Handling gas volume: 10-500 Nm3/h

Raw nitrogen purity: ≥99%

Product nitrogen purity: 99.9995%Oxygen content:≤1ppm

Dew point: ≤-60℃~-70℃

Product nitrogen outlet pressure: 0.1MPa-0.6MPa

Jinhonggas sells small-scale on-site PSA Gas Generator that offer advantages such as simple structure, easy operation, low energy consumption, and small footprint. These PSA nitrogen generator are especially suitable for the nitrogen production needs of small-scale operations. They are widely used for nitrogen protection in industries such as metal bellows, SMT (Surface Mount Technology), hard alloys, vanadium nitride, ferrovanadium, and heat treatment of mechanical parts. They are also used for nitrogen purging and oxidation prevention in copper processing, pharmaceutical and chemical industries, and float glass production processes. If you have any requirements, please feel free to contact us to inquire about the prices of nitrogen generators. We welcome your inquiries and will be happy to provide you with the necessary information.

This website uses cookies to improve your browsing experience. By continuing to use this website, you agree to our use of cookies.